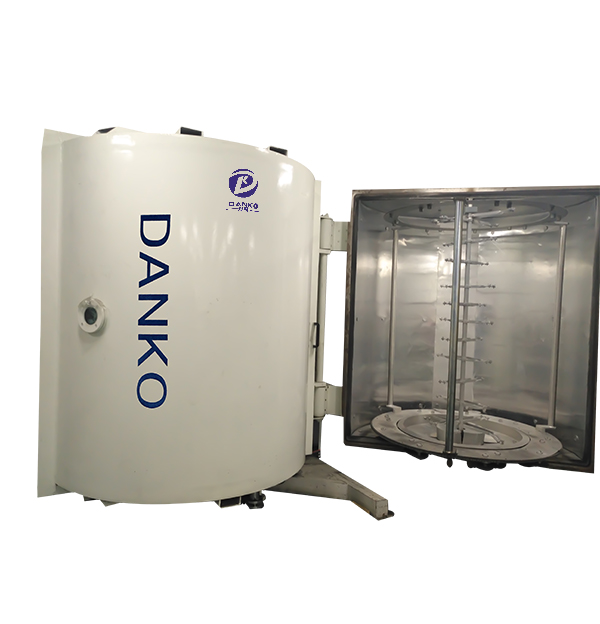

As an indispensable key equipment in modern industrial manufacturing, Wear Resistant Film Vacuum Metallizing Machine uses advanced vacuum metallizing technology to add strong and wear-resistant metal films to the surfaces of various industrial products, improving their wear resistance and chemical stability.

The operation process of Wear Resistant Film Vacuum Metallizing Machine usually includes the following key steps.

Preparation: Ensure that the equipment is in good working condition, including the normal operation of the vacuum pump system, control system, etc.

Prepare industrial products that need to be metallized, ensure that the surface is clean and flat, and improve the adhesion and uniformity of the metal film.

Vacuum pumping: Start the vacuum pump system to extract the air and impurities inside the equipment to create a high vacuum environment.

In this process, ensure that the equipment is well sealed to prevent gas leakage and vacuum drop.

Surface cleaning and pretreatment: Use the ion beam cleaning system inside the equipment to clean and activate the surface of industrial products.

Remove grease, oxides and other contaminants on the surface to improve the adhesion and uniformity of the metal film.

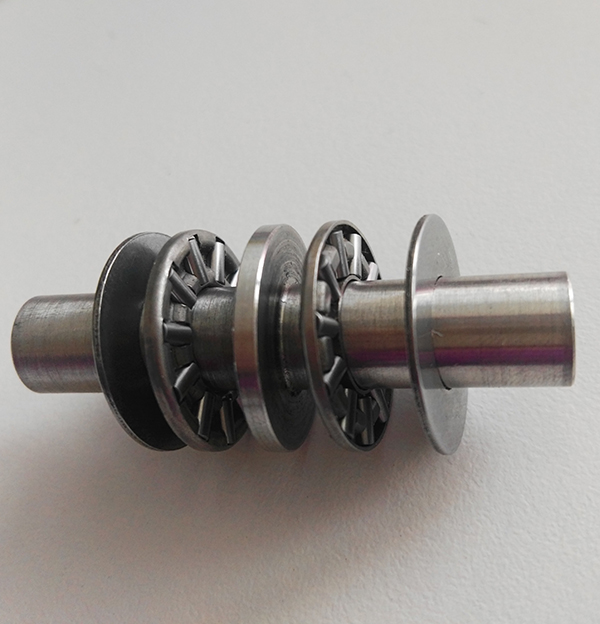

Metal evaporation and deposition: Heat the metal source and evaporate it into metal vapor.

The flow and speed of metal vapor are adjusted by the control system to ensure uniform deposition on the surface of industrial products. During the vapor deposition process, the densification and uniformity of the metal film are promoted by the bombardment of high-speed ion beams.

Coating control and multi-layer design: Select appropriate metal film materials and thicknesses according to the specific requirements and application scenarios of industrial products.

Multi-layer composite coating structures such as TiN, CrN, etc. can be designed to improve wear resistance, hardness and chemical stability.

Post-processing and inspection: After the deposition of the metal film, necessary post-processing steps are performed, such as cooling and unloading the industrial product.

The coating quality is inspected and evaluated to ensure that it meets the product design requirements and quality standards.

Equipment maintenance and cleaning: After the metallization process is completed, the equipment is maintained and cleaned, including cleaning the vacuum chamber and maintaining the vacuum pump system.

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China