Technology

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

Application Categories

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

- What is the thickness of PVD coating?

- What substrate can PVD arc ion coat on?

Recent news

-

How does the choice of target material in a vacuum coating machine affect coating adhesion, durability, and surface properties?

Jan 26,2026 -

How does the Moulds coating machine ensure consistent coating thickness across complex mould geometries and deep cavities?

Jan 19,2026 -

How does the Multi-arc Ion Coating Machine control deposition rate and film thickness uniformity across complex geometries?

Jan 12,2026

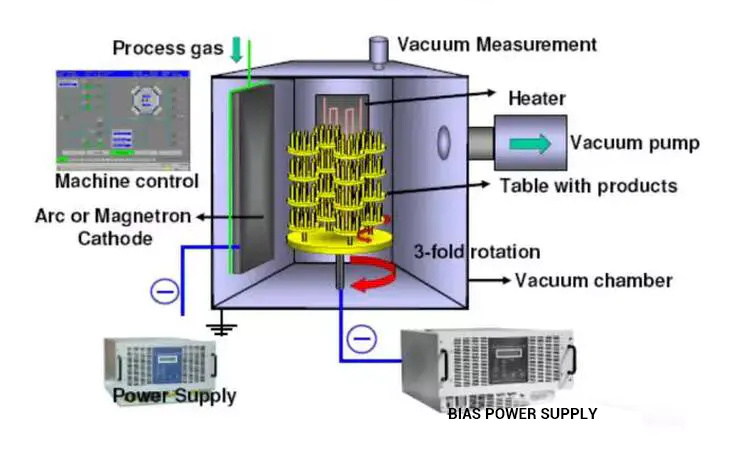

DK PVD coating

PVD is the abbreviation of Physical Vapor Deposition (Physical Vapor Deposition). It refers to the practice of using low-voltage and high-current arc discharge technology to vaporize the target material and ionize both the evaporated material and gas under vacuum conditions. By using the acceleration of electric field, the evaporated material and its reaction products are deposited on the workpiece.

PVD (physical vapor deposition) technology is mainly divided into three types: vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating.

Quick Link

Detailed information

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email: [email protected]

Email: [email protected] Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

OEM/ODM PVD Coater Manufacturers

OEM/ODM PVD Coater Manufacturers

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português