Technology

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

Application Categories

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

- What is the thickness of PVD coating?

- What substrate can PVD arc ion coat on?

Recent news

-

How does the choice of target material in a vacuum coating machine affect coating adhesion, durability, and surface properties?

Jan 26,2026 -

How does the Moulds coating machine ensure consistent coating thickness across complex mould geometries and deep cavities?

Jan 19,2026 -

How does the Multi-arc Ion Coating Machine control deposition rate and film thickness uniformity across complex geometries?

Jan 12,2026

DK Sputtering coating

Magnetron Sputtering Coating

Another form of PVD coating technology.

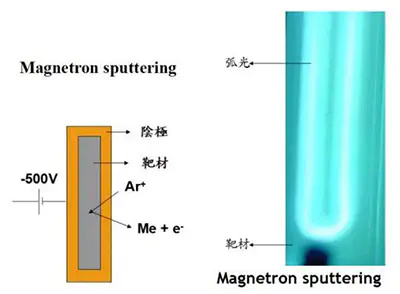

Plasma coating

Magnetron sputtering is a plasma coating process whereby sputtering material is ejected due to bombardment of ions to the target surface. The vacuum chamber of the PVD coating machine is filled with an inert gas, such as argon. By applying a high voltage, a glow discharge is created, resulting in acceleration of ions to the target surface and a plasma coating. The argon-ions will eject sputtering materials from the target surface (sputtering), resulting in a sputtered coating layer on the products in front of the target.

Reactive sputtering

Often an additional gas such as nitrogen or acetylene is used, which will react with the ejected material (reactive sputtering). A wide range of sputtered coatings is achievable with this PVD coating technique. Magnetron sputtering technology is very advantageous for decorative coatings (e.g. Ti,Cr, Zr and Carbon Nitrides), because of its smooth nature. The same advantage makes magnetron sputtering widely used for tribological coating in automotive markets (e.g. CrN, Cr2N and various combinations with DLC coating - Diamond Like Carbon coating).

Magnetic fields

Magnetron sputtering is somewhat different from general sputtering technology. The difference is that magnetron sputtering technology uses magnetic fields to keep the plasma in front of the target, intensifying the bombardment of ions. A highly dense plasma is the result of this PVD coating technology.

The character of Magnetron sputtering technology:

• A water-cooled target, so little radiation heat is generated

• Almost any metallic target material can be sputtered without decomposition

• Non-conductive materials can be sputtered by using radio frequency (RF)

or medium frequency (MF) power

• Oxide coatings can be sputtered (reactive sputtering)

• Excellent layer uniformity

• Very smooth sputtered coatings (no droplets)

• Cathodes (of up to 2 meter long) can be put in any position, therefore high flexibility of sputtering equipment design

The disadvantage of Magnetron sputtering technology.

Quick Link

Detailed information

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email: [email protected]

Email: [email protected] Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

OEM/ODM PVD Coater Manufacturers

OEM/ODM PVD Coater Manufacturers

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português